-

IHAG systems replaces conventional, expensive fuel like LPG, LDO, FO, NG firing in baking, polymerizing, curing, drying, etc processes.

-

These systems can give fresh, clean, hot air to the process upto 450• C .

-

The temperature accuracy of fully automated IHAG system is ±2•C.

-

These systems can be operated on any of the low cost solid fuel available locally & system could be installed outside factory premises and clean hot air could be conveyed to the process.

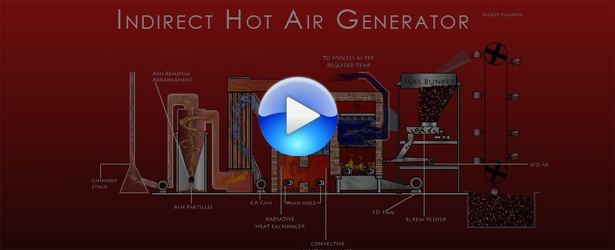

THE INDRIECT (FBC) HOT AIR GENERATOR CONSISTS:

AIR SUPERHEATER (RADIACTIVE HEAT EXCHANGERS):

It consists of bank of S.S. pipes, welded with a free floating box header, which rest on rollers, supported on a mechanical structure frame.

AIR HEATER (CONVECTIVE HEAT EXCHANGERS):

It consists of bank of S.S./M.S. pipes, welded with a free floating box header, which rest on rollers, supported on a mechanical structure frame.

AIR PRE-HEATER (HEAT RECOVERY UNIT):

It recovers heat from the flue gases and transfers it to input fresh ambient air by counter current flow.

POLLUTION CONTROL EQUIPMENT:

High efficiency air pollution control equipment would be provided to reduce ash particles from flue gases emitted in the ambient through stack.

FLUDIZED BED COMBUSTION FURNACE:

Solid fuel fired FBC system consist a nozzle tube sheet with attached air plenum & a side structure frame. Graded CI (Cast Iron) nozzles are fitted on top of the nozzle plate.

Nozzle plate provided with sand drain pockets to remove heavy unwanted silica particle & clinkers from furnace.

FUEL FEEDING WITH SCREW CONVEYOR SYSTEM:

Motor driven screw conveyer will feel the fuel continuously into the furnace through designed fuel feeding venturi system aided by the S.F.D. Fan air.

BALANCED DRAFT SYSTEM:

The forced draft fan provides air for fluidization cum combustion through the air nozzles fitted on furnace plate. Induced draft fan is implemented for balanced suction in furnace.

HEAT INSULATION & REFRACTORY:

The HAG is insulated with mineral wool blanket packed with wire netting, cladding with aluminum sheet.

All the standard / special shaped refractory bricks for furnace walls along with fixtures & holders would be provided.

INSTRUMENTS & SAFETY INTERLOCKS:

The system offered is extremely user friendly. Alarms & safety interlocks have been provided to ensure different parameters of HAG.

In case of high hot air temperature audio/visual alarms are activated on panel.

In case of high & low condition of hot air duct pressure audio/visual alarms are activated on the panel.

Visual alarms are activated in case of fault in V/F controllers.

PID temperature controllers & pressure transmitters are provided for different required system parameters.

CONTROL PANEL:

The panel is PLC based having sophisticated but user friendly controls enabling the operator to run the HAG in automatic or manual made as desired.

AUXILLARIES:

Main MCCB ,V/F drives, annunciation module with hooter, PID controllers, indicating lamps.

|

|

Our Products |

||||